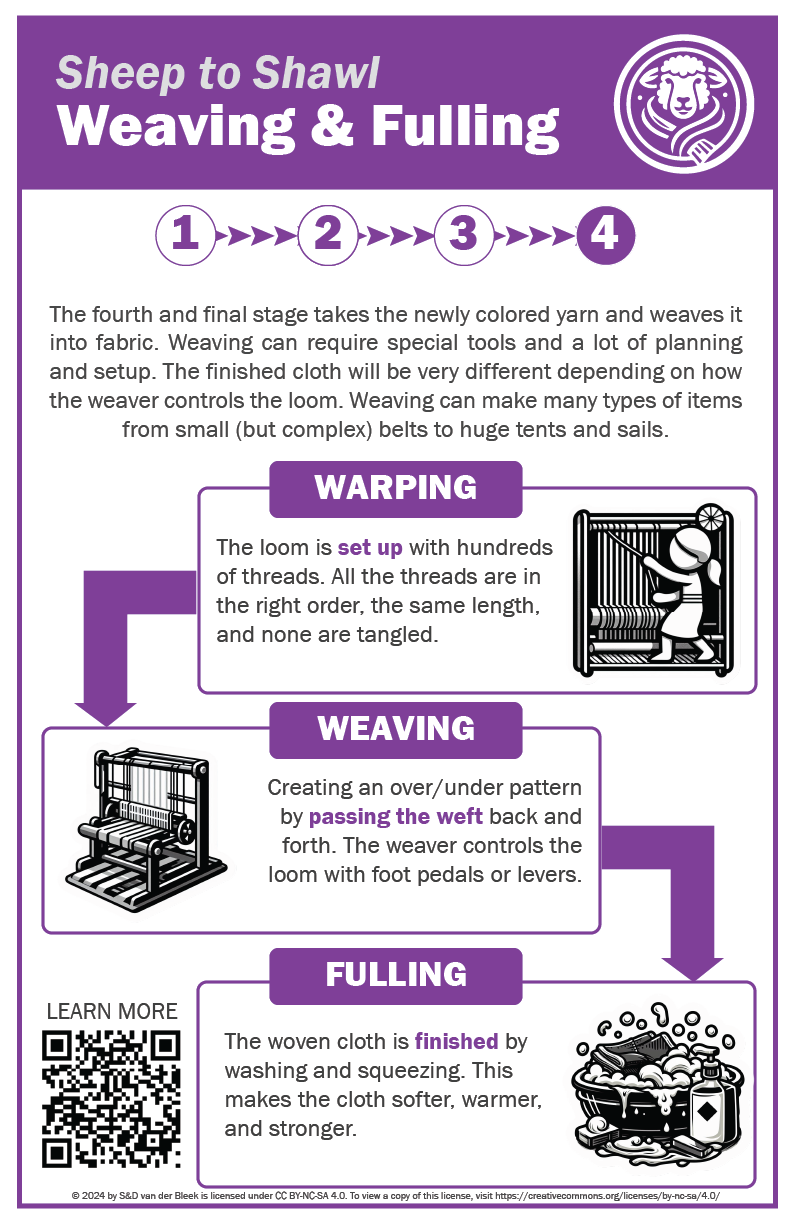

Step 4: Weaving and Fulling

The fourth and final group of steps take the newly colored yarn and weave it into fabric. Weaving requires special tools, and quite a bit of planning and setup. The finished cloth can be very different depending on how the weaver interacts with the loom, showing a definite fingerprint. Many different types of weaving exist, from making small but complex bands to huge looms that make tents and sails.

Warping

Setting up the loom requires hundreds or thousands of yarns to be in the right order, and all the same length. Warping is process of counting, measuring, and winding the yarn onto the loom to be ready to weave. Each thread (or “end”) has to be threaded through both the heddle, which controls the pattern, and the reed – and in the right order!

Weaving

Weaving utilized the warped loom, and is the act of passing the weft yarn left and right to make cloth. The weaver controls which threads go over, and which go under, by pedals or levers. This over/under pattern makes the final cloth. Different patterns like “over over over under” can make the final cloth have different properties.

Fulling

The woolen cloth fresh off the loom needs to be finished before it can be used. Fulling washes the cloth, releasing the tension that has built up on the loom. Agitation can be used to shrink the cloth, making it denser and warmer. Traditionally fulling was a separate job, performed with the aid of huge hammers to produce durable and weather resistant cloth for coats and outerwear.